•

Solenoid valves are automatic valves designed without gland seals, suitable for isolating gaseous and liquid volume flow rates in many different pressure and temperature ranges, and there are practically no limits to their application. Thanks to the fail-safe function "spring-pressure closing‘ or ‚spring-pressure opening‘ solenoid valves are used as safety-related actuators.

Solenoid valves are automatic valves designed without gland seals, suitable for isolating gaseous and liquid volume flow rates in many different pressure and temperature ranges, and there are practically no limits to their application. Thanks to the fail-safe function "spring-pressure closing‘ or ‚spring-pressure opening‘ solenoid valves are used as safety-related actuators.

Advantage

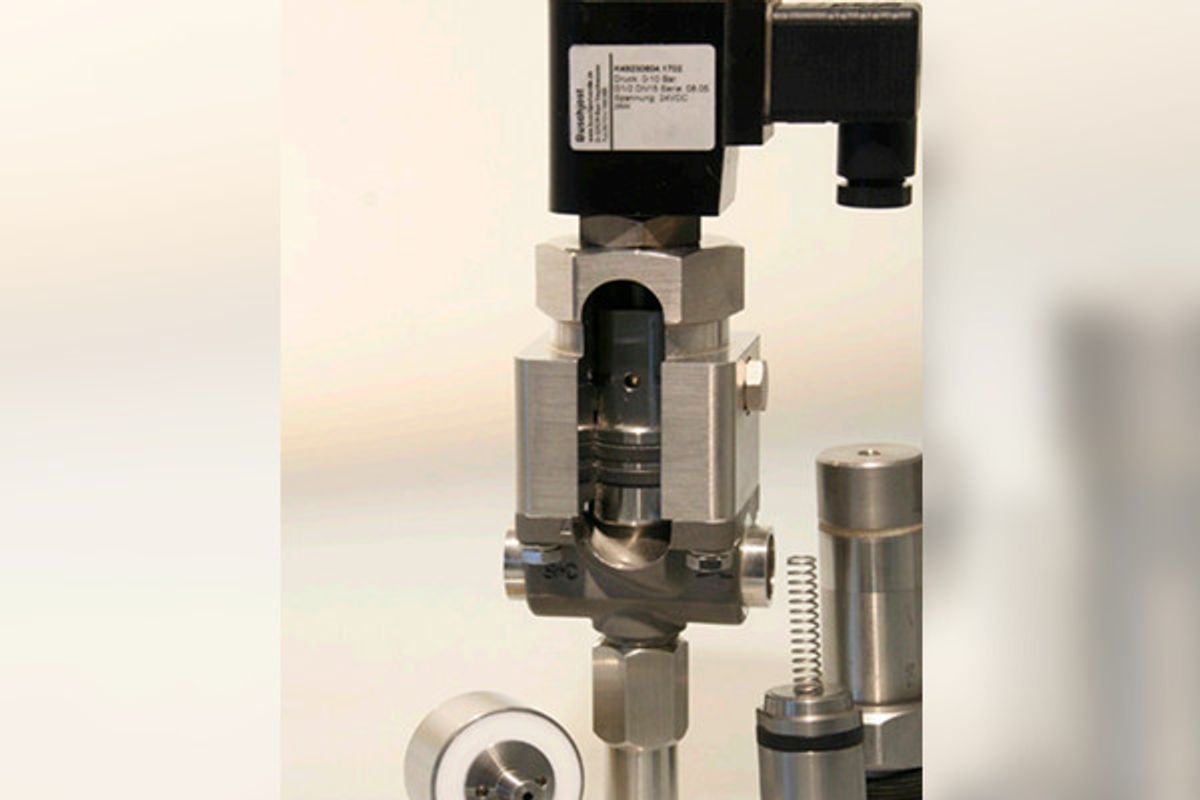

In our solenoid valves we renounce the valve spindle seal guided to the outside.

- screwed valve parts,

- welded solenoid core tube,

this ensures permanent high sealing towards the outside. Optional limit position switches type RC12/27 for remote control of the actuator are also designed without gland seal. A permanent magnet fitted to the spindle, switches the Reed contact for the OPEN/CLOSED signal.

High switching cycles

Solenoid valves are very suitable for high switching cycles. They have been optimally adapted to the application so that 1 to 2 million or more switching cycles can be achieved. Our high-quality valves - be it for high pressures, hot media or for especially hazardous liquids and gases - have PTFE piston guide rings 1, guided inductors and pistons. This is one of our specialties which has been applied in many series so far, as this reduces the wear and tear friction to a miniumum.

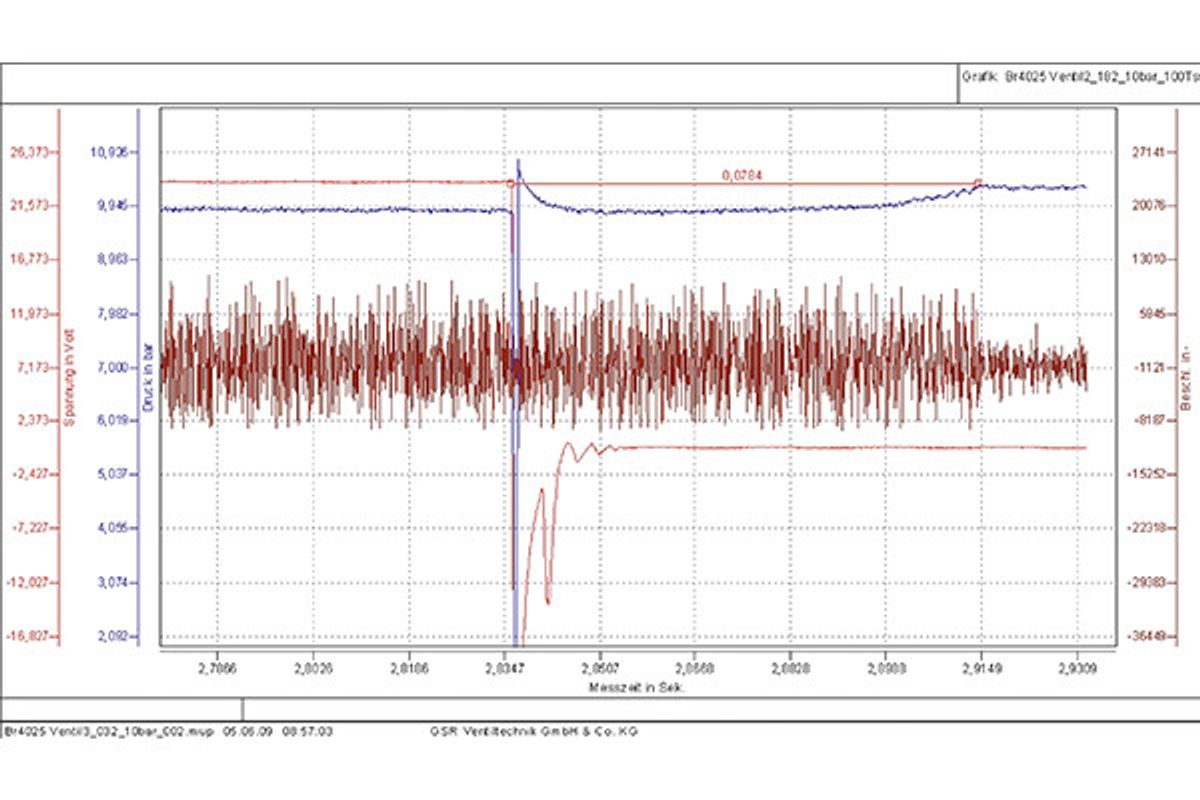

Fast switching solenoid valves

The opening and closing times of seat valves depend on the design and process. Everything is possible: from extremely short times, i.e. from 50 to 80 msec. from applying the voltage to the full volume flow up to delayed closing from 1 to 3 sec. . The feared water hammer can be effectively mitigated via the closing time reducting screw.

Controllable closing damping

The closing time of solenoid valves can be delayed with a needle valve on the valve cover to prevent undesired effects (water hammer). For many valves closing damping is standard as from DN32, for smaller nominal diameters (DN20-DN25) it can be supplied optionally. However, for safety reasons, closing control is not offered for ammonia (NH3) - solenoid 1 KFR valves.

Refrigerants NH3, R23, R125, R143a, R507...

For the ‚refrigerants‘ field of application solenoid valves of the 35/49 series and/or the 37/24 series are used. Ensure to select good materials for these valves as they are sometimes use for combustible and toxic substances (ammonia NH3). Here the advantage of the high outer tightness in seat valves is especially relevant as mentioned at the beginning as even very small leakages can jeopardize human beings.

Material compatibility

All fitting components are screwed connections with Teflon seal (O-rings, seal-rings). In the refrigeration technology field we generally recommend PTFE as sealing material. We would not, or only conditionally, recommend FKM (fluorine rubber) or EPDM (ethylene-propylene-rubber) because of their swelling properties and/or blistering (free from mineral oil!).

The base fittings up to and including DN50 are designed with welded ends acc. to ISO 4200 (Series 35/49) or as flanged end with groove acc. to DIN 2512 from DN15 to DN100 (Series 37/24).

The temperatures are different and depend on the choice of the refrigerant. For NH3 the valve design up to -40°C will be sufficient, for other refrigerants of which the evaporation temperature is -80°C the valves will be adapted accordingly, if necessary.

Repair and sealing kits

For each of the valves you can order spare parts such as O-rings, groove or piston rings, pistons or diaphragms, either individually or reasonably combined as a set.