Founded on 10.12.1998 in Bad Oeynhausen. Founding members Fritz Buschjost & Marc Langejürgen.

GSR Ventiltechnik & Buschjost Solenoid Valves in the group of Indus Holding AG, Bergisch Gladbach.

Entry and majority shareholding of GSR Ventiltechnik GmbH & Co. KG.

Selecting the right type of valve can be challenging. It's good that you can rely on our years of know-how and can easily reach us at any time if you have que stions or doubts.

We will work with you to determine the specifications and appropriate material combinations of the valve that will withstand the pressure and temperature conditions of your application. For each product you have access to detailed data sheets, certificates, operating instructions and technical drawings. Various tools such as the KV value calculator, resistance tables and our innovative and interactive consultation tool Ventil Scout additionally facilitate your product selection and use.

Our team has developed the practical online consultation tool Ventil Scout based on the experience gained from many years of consultation. Ventil Scout bundles all the important questions that our team would ask you on the phone in order to offer you the right product for your applications. It's uncomplicated, fast, and available at any time of day.

Try out the Valve Scout for yourself right now.

We are consultants and suppliers of solenoid valves and problem solvers for the control and shut-off of medium-carrying pipelines.

Let us know your valve requirements and we will work out a detailed offer including technology, price and delivery time. We will be happy to show you alternative solutions, without obligation and free of charge.

We offer a comprehensive range of standard and special valves for almost every industrial application. Everything from a single source, with personal advice and service.

You have a seemingly unsolvable valve requirement? With our know-how, we succeed in pointing out solutions to eliminate malfunctions and provide a remedy.

As a responsible member of corporation, we are committed to principles of conduct that you can view here.

Buschjost solenoid valves offer economically interesting valve solutions in well-known high quality. Buschjost customers receive our support throughout the entire product life cycle of a valve. We guarantee the supply of spare parts from the individual seal to the complete revision set.

Thanks to the modern production process, all valves placed on the market can be traced, even after many years. This is done via the nameplate and by a permanent imprint on the valve. Each valve is subjected to a strict quality control before delivery. A 100% test for function and tightness according to the currently valid standards is a matter of course for us.

Each product can be identified by its nameplate and permanent imprint.

Throughout the entire product life cycle, we provide spare parts from individual seals to complete sets.

Each valve is subjected to a comprehensive technical test for function and tightness.

Our products are tested according to the currently valid standards. We are also happy to offer individual testing.

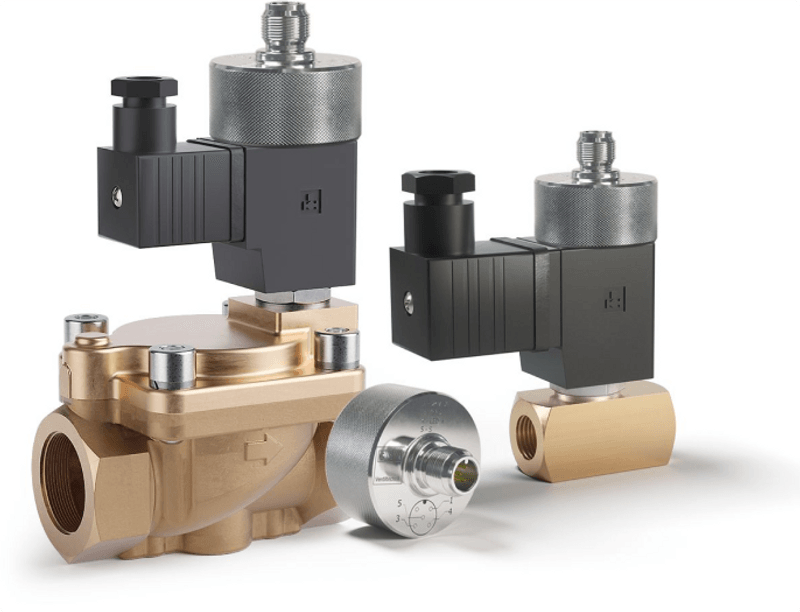

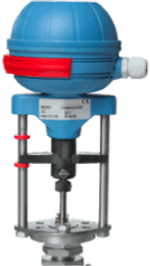

The Buschjost process valve program includes a wide range of different solenoid valves and air-controlled valves for controlling and regulating gaseous, liquid media in pressurized pipelines.

Solenoid valves block, relieve, distribute or mix gaseous and liquid media of various chemical compositions depending on pressure and temperature.

Versatility is key. Forced-Pilot-Operated valves combine the advantages of Servo-Assistant and Direct-Acting valves.

Achieve a lot with little energy. The specification of the minimum pressure difference precedes the maximum possible pressure difference.

The professional with extra power. The magnetic force must act against the medium pressure and the spring.

Control air present? If YES, then you can take a look at these valves.

We combine the advantages of the control types direct, servo and externally controlled. The larger the valve and the higher the pressure, the more effective the use of these valves. For water control, these valves are preferably equipped with a damping cone to prevent the water hammer.

Obsolete Valve category with reduced range of options and limited to a very small number of applications. This category has a permanent place in the "Riding a Dead Horse" section and will be removed from the programm.

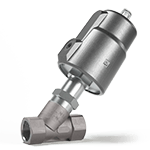

Best Value for Money Use the existing compressed air system to control the stroke actuator and you have a long-life valve for a wide range of applications. The well-known 63 series, whose forerunner, the 62 series, was launched in 1971 with its characteristic formed blank cylinder, is the best indication of this high-quality product category. Even today, 25 years after the end of production of the 62 series, repair and service enquiries are still coming in from all over the world.

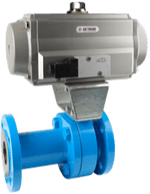

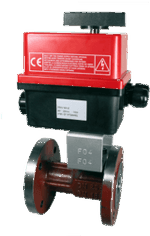

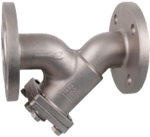

A ball provided with a bore and guided by sliding shells in a geometrically adjusted housing is called a ball valve. The 90° angle of rotation opens or closes the way.

Ball valves with hand lever

Ball valves with pneumatic actuatur, single or double acting

Ball valves with electric actuator

Solenoid valves block, relieve, distribute or mix gaseous and liquid media of various chemical compositions depending on pressure and temperature.

Control air present? If YES, then you can take a look at these valves.

A ball provided with a bore and guided by sliding shells in a geometrically adjusted housing is called a ball valve. The 90° angle of rotation opens or closes the way.