Project: Ground freezing with liquid nitrogen

The ground is to be frozen during civil engineering works, e.g. tunnel construction to protect from sinkholes and water penetration. For this purpose a number of freezing lances is positioned in the tunnel, shaft or adit and subsequently filled with liquid nitrogen. The nitrogen with a temperature of -196° C forms a freeze wall extending deep into the surrounding ground within some days ...

The freeze lances required for this purpose consist of an inner and outer pipe and are introduced into the boreholes.

By feeding liquid nitrogen (LN2) through the inner pipe the surrounding ground is sufficiently cooled to ensure the formation of a freeze wall. Then the gaseous nitrogen (exhaust gas) flows through the annular gap between the inner and outer pipe to the outside.

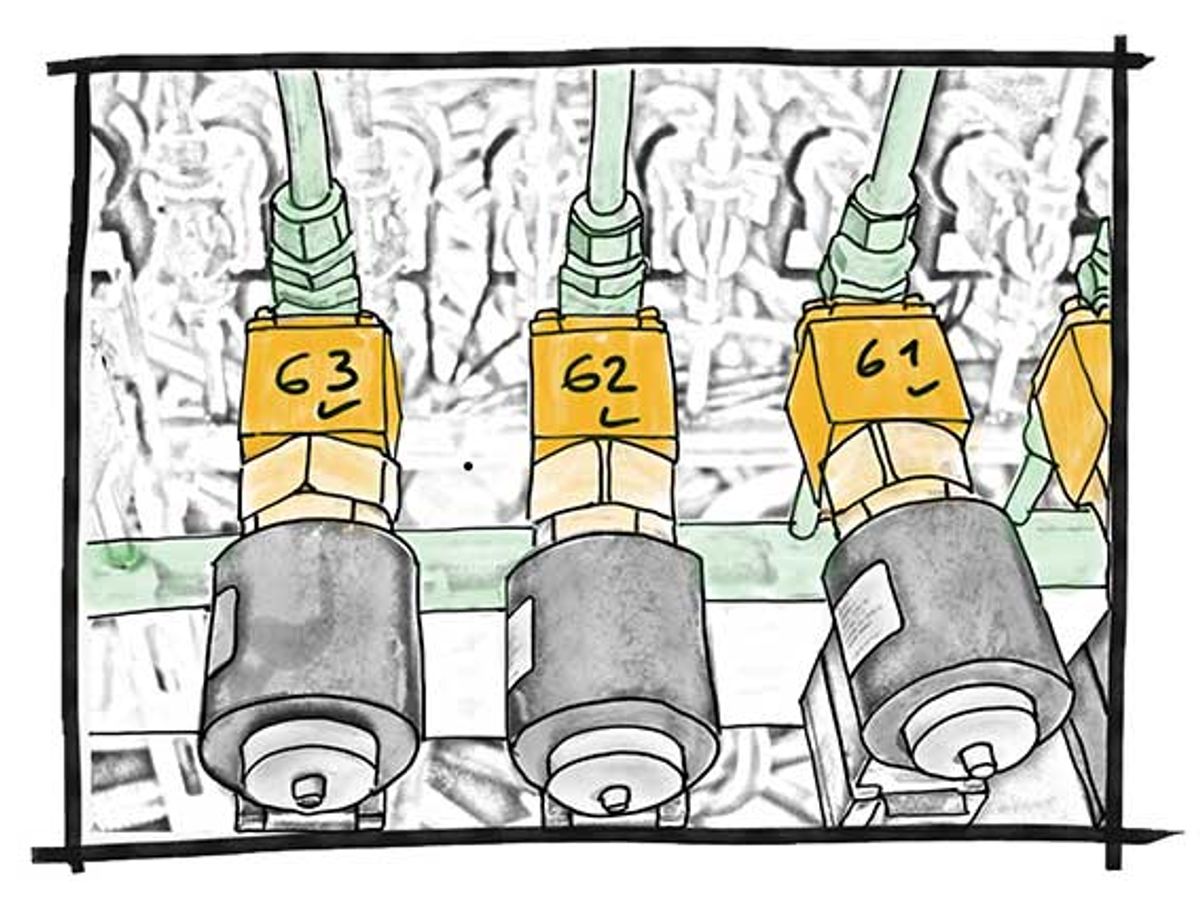

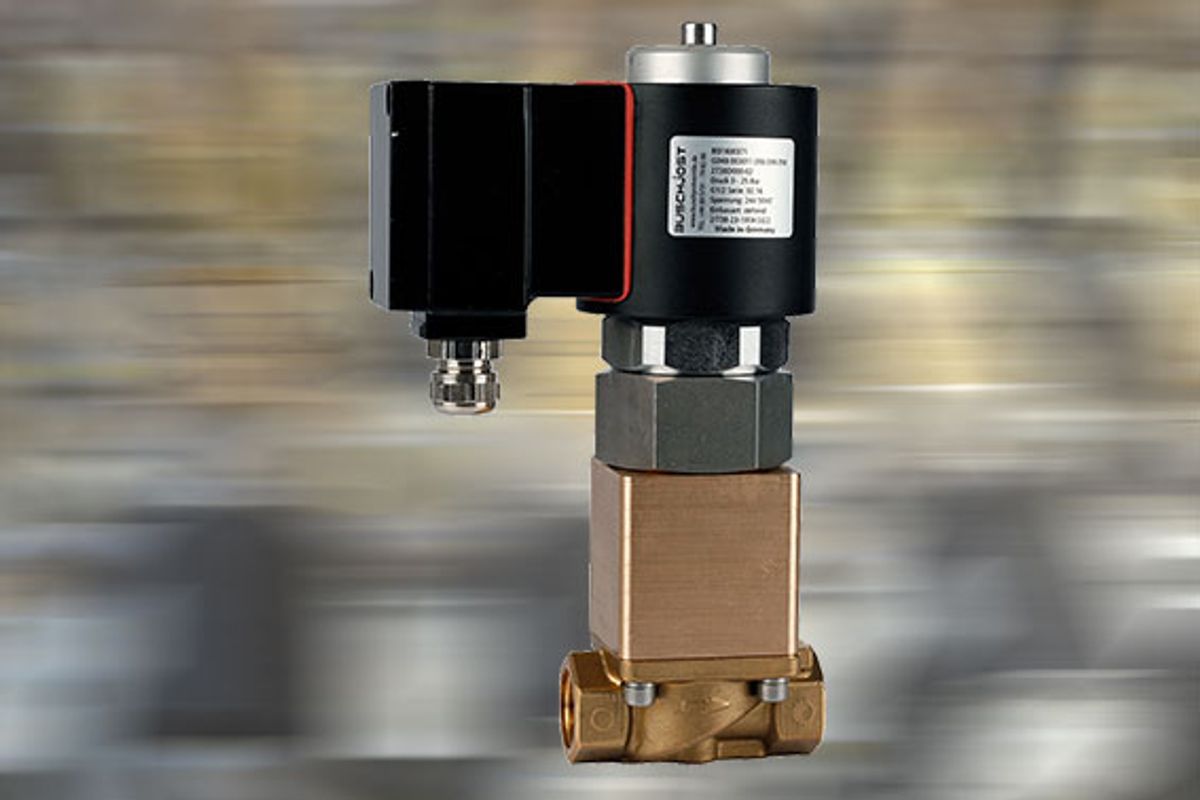

Nitrogen feeding to the freeze lances is carried out in a temperature-controlled way. A solenoid valve type 2/738 has been installed upstream of each freeze lance. Control of the solenoid valves is ensured by temperature sensors on the exhaust gas side.

The reliability of the solenoid valves is very important as nitrogen dosing is to be ensured by these valves. Often up to 80 solenoid valves are to be switched at 1-second intervals for many days or weeks during the tunnel construction term. A failure of the valves would cause a disturbance of sectional freezing fields and sustainably jeopardize the tunnel construction project.

Developed, tested and successfully used:

Solenoid Valve, Cryogenic-Design

-

Typ 2/738-23-1004-S322

-

G1/2,

-

0-25 bar,

-

230V AC ,

-

NC,

-

liquid nitrogen (LIN) -196 °C